Types of EEF Technologies

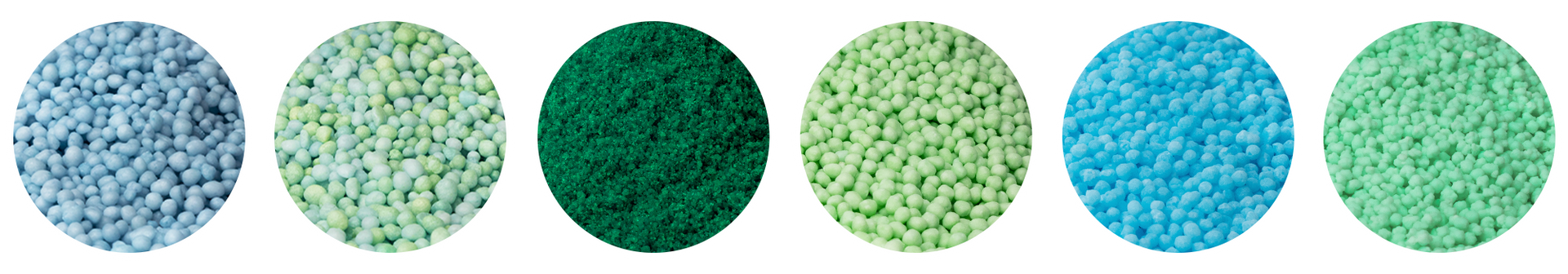

Controlled-Release Fertilizer

A

controlled-release fertilizer is a nutrient source (often urea or sulfate of potash) coated by a polymer layer, regulating gradual nutrient release into the soil. This specialized coating ensures controlled dissolution of nutrients while allowing gradual outward flow through the polymer. Factors like temperature and soil moisture influence release rates. These fertilizers can vary in coated thickness to provide nutrients to plants over weeks to months, reducing application frequency compared to conventional fertilizers. Controlled - release fertilizers enhance nutrient efficiency, minimized leaching, and improve turf and ornamental quality. Polymer-coated controlled-release fertilizers are pivotal in agriculture, horticulture, and landscaping, offering a balanced and efficient approach to plant nutrition and soil fertility management.

Slow-Release Fertilizer

Slow-release nitrogen (N) sources, also called "slowly available," are a part of many turfgrass fertilization programs. They provide greater longevities of available N than quick release sources, and are safer to use on turfgrass because of their lower burn potential. This group includes both coated and uncoated sources.

Sulfur-coated urea (SCU) fertilizers are granules of urea coated with sulfur and wax. Imperfections (cracks, fissures, fractures) in the coating allow water to move in and dissolve, then release the urea. For fertilizer particles with coatings that are intact after application, water movement through the coating results in internal osmotic pressure that cracks the coating, releasing nutrients. This process has been called catastrophic release. In addition, microbial degradation of the wax and sulfur allows water to reach the urea, dissolving and releasing it.

Stabilized Nitrogen Fertilizer

Inhibitors/stabilized nitrogen fertilizers work by delaying the conversion of N to forms that can be more readily lost to the environment through leaching, denitrification and volatilization. This delay allows time for rainfall or precipitation to move the urea into the soil where it is less prone to volatilization, and/or retains N in the plant/soil system longer. There are two main categories: urease inhibitors and nitrification inhibitors.

EEF Release Factors

What Factors Can Affect EEF Nutrient Release

For any fertilizer—including enhanced efficiency fertilizers (EEFs)—these environmental factors contribute to how and when each releases nutrients, and the rate of that release.

Water

In water soluble or quick-release fertilizers such as urea and ammonium nitrate, water dissolves the source and nutrient release is immediate. Although turfgrass response is rapid with these fertilizers, too much water makes nitrogen (N) prone to leaching and runoff.

Stabilized nitrogen is based on urea, so water is important in solubilizing the fertilizer. The presence of inhibitors retains N in plant-available forms longer than non-amended urea though, making the N less prone to loss.

In controlled-release and slow-release fertilizers, water is utilized to dissolve the nutrient inside the granules. Although it does serve as an activator, water may impact the release rate of sulfur-coated products, but does not impact the rate for polymer-coated fertilizers.

Temperature

Both ambient and soil temperature can affect the release of nutrients to the plant. High temperatures can also increase the potential for ammonia volatilization.

In the case of controlled-release fertilizers, temperature impacts the rate of diffusion, the primary control on nutrient release. Controlled-release fertilizer release rates therefore increase with rising temperatures, and vice versa.

Microbial Activity

Soil microorganisms also impact how and when some EEFs release. Methylene urea (MU) and urea-formaldehyde (UF) fertilizers, as well as natural organics, rely on microbes to break down the fertilizer, releasing nutrients through mineralization.

Microbes can also degrade the coatings of sulfur-coated fertilizers, enabling nutrient release. Microbial activity is generally higher in warmer soil temperatures and less active in colder conditions, so temperature impacts the release rates of these EEFs.